What is Spiral Pipe? What Does It Do, What Are Its Types?

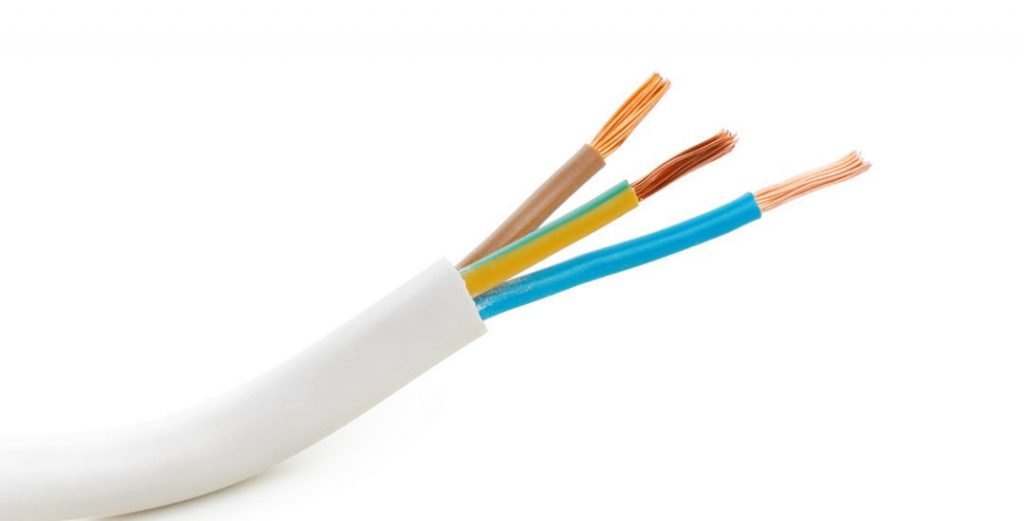

What is Spiral Pipe? What Does It Do, What Are Its Types?The protective pipe used to prevent damage to the cables supplying the electric current is called spiral pipe. In places where the electrical cables are mobile, the cables are easily corroded and damaged. For this reason, spiral pipe or steel spiral pipe should be used to protect the cables. There are different types of spiral pipes, and the usage areas of spiral pipe and steel spiral pipe are different from each other. The use of steel spiral pipes should be preferred for cables in areas that are likely to be exposed to loads and impacts. The reason for this is that steel spiral pipes have the ability to prevent the cables from being damaged and damaged.

What is Spiral Pipe? What Does It Do, What Are Its Types?The Steel spiral pipes should be used in places where it is not possible to fix the cables. There is a high probability of rodent animals in shaft cavities in construction areas, and rodents can cause significant damage by gnawing on electrical cables. In order to prevent this, it is an effective solution to use some kind of spiral pipe.

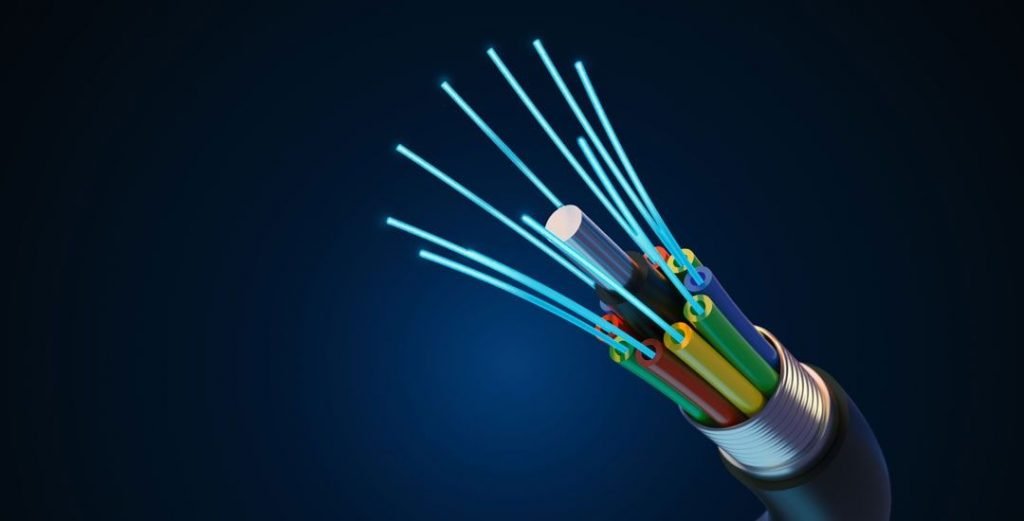

Spiral pipes have the feature of being cables that can be bent at the desired angle. It can be used in beam turns, column lines and places where turns are high in electrical installations. Spiral pipes that facilitate labor can be produced from metal or insulating materials. As metal, there are types made of galvanized steel, tinned steel and insulated steel.

How to Produce Steel Spiral Pipe?

A sheet with the diameter of the spiral hose to be produced is wrapped in the machine in a round shape. It is then clamped together with the bending machine using clamps. The interlocking of the clamps is related to the inner and outer twisting in the production process.

After the production of spiral hose for the production of PVC cable steel spiral pipe, PVC coating is made using an extruder machine. After the coating is made, it is cut to the desired length and made ready for use.

Guide wires inside the steel spiral cables are used to pass the cable through the bendable spiral pipe. The guide wire inside the spiral tube is connected to the electrical cable and then pulled. Another alternative is to use susta.

What is Spiral Welded Steel Pipe?

Spiral welded steel pipe is a low carbon or low alloy structural steel strip, which is wound into a tube cavity at a certain forming angle. It is then welded and a narrow strip is formed into a usable pipe joint.

The strength of spiral welded steel pipe is generally higher than that of straight welded pipe. The main production process is submerged arc welding, and spiral welded pipes can be welded pipes with the same gap width and different pipe diameters or larger diameter weld pipes with narrow gaps.

What are the Features of Spiral Welded Steel Pipe?

Spiral welded steel pipes have a wide variety of production. Pipes can be produced in wall thicknesses up to 25 mm and in diameters up to 3000 mm. Lengths of up to 53 meters can be produced without environmental welding. Longer pipes can be obtained by welding. In addition, the most important features of spiral welded steel pipes are a wide variety of steel grades and production standards, the inclusion of couplings, pile shoes or other fabricated components, and the availability of inner lining and outer protective coating options.

Spiral welded steel pipes can mostly be used in tap water engineering, chemical industry, agricultural irrigation, petrochemical industry, electric power industry and urban construction. In the field of liquid transport use, it can be used for water supply, sewage treatment works, sea water transport, drainage and sludge transport. For gas transportation, it can be preferred in steam, gas, liquefied petroleum gas.

Spiral welded pipes are subjected to extremely stringent physicochemical tests before being used. Spiral seam submersible arc welded pipe for pressure bearing fluid transport is mainly used in pipelines carrying oil and natural gas. It is recognized that the steel pipe has strong pressure bearing capacity and good plasticity, suitable for welding, machining and forming.

Advantages of Spiral Welded Steel Pipe

The longitudinal production process of spiral welded steel pipes is simple, low cost, high efficiency and fast. The production can be done by changing the age, or by keeping the diameter constant and making changes on the wall size of the pipe. However, it is preferred that the ones with small diameters are generally straight longitudinally welded, and the ones with large diameters are spiral welded.

The tension of spiral welded steel pipes is much higher than other steel pipe types. In this way, they deform much less. The diameters, thicknesses and length dimensions of spiral welded steel pipes can be changed according to the requirements of the design. The strength is higher due to the double welded seam design around the pipe. They are also known to be more resistant to stretching and friction. According to the researches, spiral welded steel pipes can withstand 25% more pressure.