Briefly, what are the characteristics of weak current cables?

Weak Current cables must have certain important features according to various usage areas. The most important features sought in weak current cables are that they do not transmit flames, do not spread flames, have low smoke density, do not contain toxic gases and do not contain corrosive gases.

The reason why these features we have mentioned come to the forefront among the features sought in weak current cables are smart buildings with valuable goods, especially in places where people are collectively, and hospitals and cinemas, which are the places where people are most concentrated, as well as theatres, schools, shopping malls, airports, factories, It is used effectively in places such as tunnels.

In addition to these features, if there is a possibility of forcing that may occur in the environment where the weak current cables will be used, if the weak current cable will be exposed to impacts and if there is a risk of harmful organisms such as rodents in the environment, it is decided whether the right sheath selection or armoring is required in the cable.

In addition, weak current cables must contain various protective features according to external factors such as oil, chemicals and moisture in the environment.

If there is another signal in the environment that will affect the signal to be transmitted through the weak current cable, it must have a shielding feature.

What are weak current cables?

Weak current cables are generally used in indoor applications in buildings, in applications with data exchange such as sound, bell, video, telephone, lighting, alarm systems, ADSL, CCTV security camera applications and other security systems applications in systems below 1kV. We would also like to point out that when grouping cables in weak current cable types, weak current cables are included in low voltage cables.

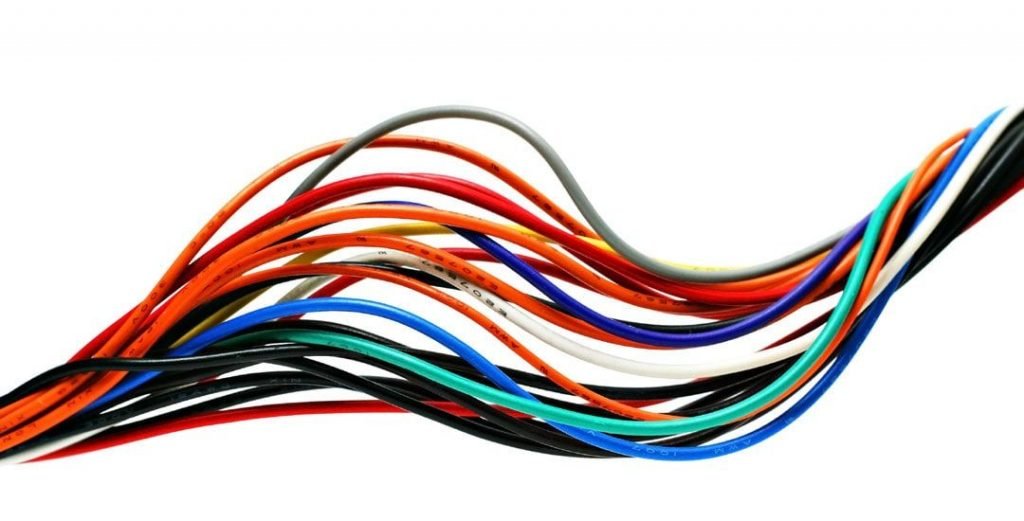

In general, cables, including weak current cables, are a conductor that is used as a standard for the transmission of electric current and consists of copper wires, which are kept insulated from the outside world by means of an insulating plastic material. These copper wires are divided into two as single wires known as mono or multiple wires known as flexible and play an important role in the transmission quality of electric current from the cable.

Weak current cables, which perform at the level of excellence in electrical transmissions due to technological developments, provide an indispensable good comfort when the usability areas are well determined.

What are the characteristics of weak current cables?

Weak current cables generally consist of 10 different structures such as conductor, separator tapes, inner sheath and fillings, core, core insulation, wick-blind core, separating sheaths, metallic armors, screens and protective outer sheaths.

● Resistance represents the difficulty of any material against electric current, and on the other hand, the most well-known and important feature of the conductor structure is its electrical resistance. The Conductor Structure is used to transmit electrical energy or electrical signals. The conductive structure consists of one or more wires. The dimensions of this conductor structure, which is an insulated or non-insulated wire/wire bundle and used in cables, are measured in mm² within the scope of its geometric cross-sections or in mm within the scope of its diameters. In addition, there are conductor structures that can be measured with AWG, another dimensioning system, which is the American measurement system.

● In cable manufacturing, the materials that separate the elements in the cable from each other are separator tapes. While some of these separator tapes undertake the separation task, some are used in tasks such as moisture barrier, fire barrier and shielding.

● There are also inner sheaths and fillings among the structures. Here, the inner sheath is the insulating sheathed inner sheath placed between the separating layers. The fillers are the sheath that is used to give the desired circumferential shape to the core bundle in the cable in multi-core cables. Inner clothing and fillings, which should generally be suitable for the insulation and outer sheath material, can be PVC, PE or HFFR.

● A second structure is the core structure, which is each insulated conductor of a cable. The relevant core structure consists of the conductive part in the cable and the insulating material surrounding this cable.

● If we talk about insulators, these are materials that resist electric current and do not conduct current current, and they are used in the electrical industry to isolate conductors from each other and insulate them from their surroundings. For this reason, another structure that we will talk about is the vessel insulation structure. The core insulation structure is the sheath that electrically insulates the conductor.

● This structure, which is another structure called Roving-Blind core structure, is used to fill the gaps between the cores of multi-core cables. In addition, this wick-blind core structure is insulating materials that have the task of providing a suitable shape for the existing cable. PVC in this structure. PE or HFFR materials can be used in the structure of suppositories.

● The separator sheath structure is an insulating sheath placed between overlapping individual metals. In general, the materials of the separator sheaths, which should be suitable for the insulation material and the outer sheath material, can be PVC, PE or HFFR.

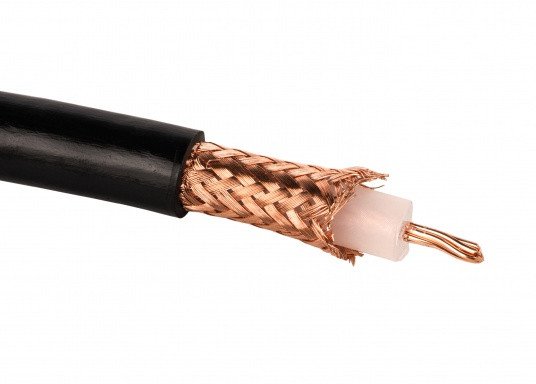

● During the laying of the cables used for an application, an additional protection with metallic shields is generally required against the mechanical negative effects that may occur on the cables. Metallic shields also function as grounding and screen protectors.

● At the same time, shielding is done on the cables. The purpose of these shieldings on the cables is to ensure that the electrical signals carried by the cable are not affected by electromagnetic interference that may occur in the environment where the cable is located.

● Protective outer sheaths that protect the existing cable from external influences are the material in the outermost layer of the cable.