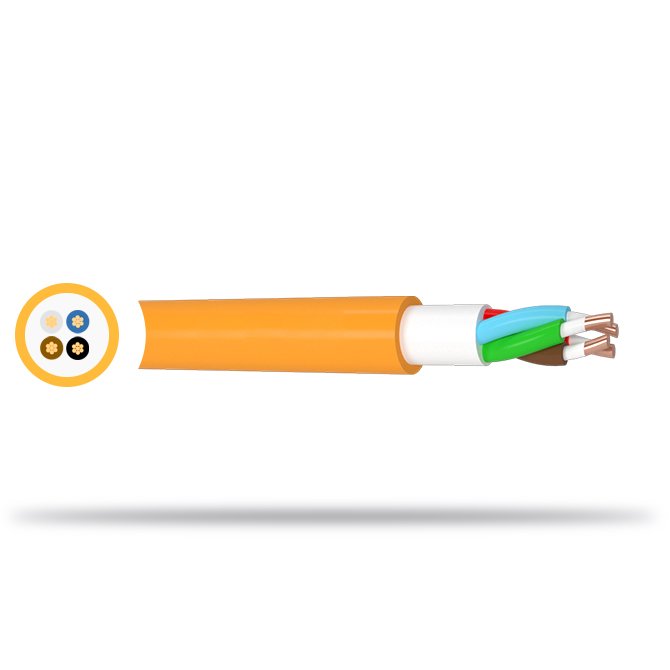

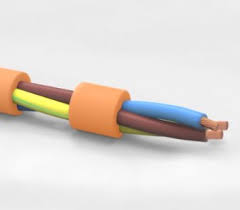

Polyurethane (PUR) – Thermoplastic Elastomer Cables:

Polyurethane (PUR) – Thermoplastic Elastomer Cables:

Polyurethane raw material has gained importance in the cable sector in recent years in line with the requirements of the industry. PUR material exhibits a rubber-like mechanical behavior up to a certain temperature. The ability to combine thermoplastic and elastomeric behavior has also led to the term thermoplastic elastomers (TPE). In line with the needs of the industry, in addition to the PUR standard, Baran Kablo is able to produce the following PUR Cable types in its Turkey Factory, thanks to its R&D investments and development in cooperation with the plastics industry:

1. PUR silk matte (low adhesion)

2. PUR matte (rough surface, low adhesion)

3. PUR flame retardant

4. PUR halogen free and flame retardant

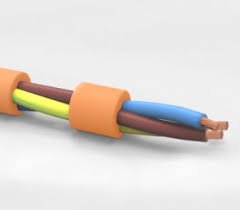

Pur Cables Mechanical Strength:

If the cables specially produced for the usage area are produced in a flexible way, it is expected that the outer sheath will be damaged due to tearing and cutting. In addition, the cables may be crushed or impacted by the tools in the working environment. The main mechanical properties that the PUR Cables we recommend for all of these situations are as follows:

1. High tensile strength

2. Tear and tear resistance

3. Notch resistance

4. Wear resistance

5. Alternative bending strength

6. Impact resistance

7. Cold flexibility

Pur Cables Resistance to Chemical Products:

Chemical resistance in cables varies according to the location. Type of Chemical, exposure time, temperature, amount, concentration measure, depending on the type of Raw Material used. When PUR Raw Materials are compared to various other materials (eg Rubber or PVC), PUR has been found to resist the same chemical reactions considerably better.

Advantages of PUR Cables against chemical reactions:

1. Resistant to mineral oils

2. Resistant to alcohol-free gasoline

3. High stability in water

4. Good resistance to many solvents

Our Pur Cables are resistant to Microbes, depending on the heat or humidity of the environment.

Even if our Pur Cables are stored for longer periods of time in hot water or in tropical climates, slight reductions in mechanical strength can be seen. Baran Kablo Polyurethane Cables are resistant to weather conditions and ozone in all climates. It is possible that the colors “yellow” under the influence of sunlight, but this does not affect the use.

Example application areas for PUR cables:

1. For controllers, e.g. machine tools, assembly and assembly lines,

2. conveyor systems and production lines (including work platforms and transport systems),

3. Machinery and plant construction,

4. In energy chain transport systems

5. Automotive industry

6. Conveying and automation technology

7. Iron, steel and chemical industry

8. Power Tools (power tools such as drills, grinders, etc.)

9. In brick factories and cement factories

10. Industrial painting systems

11. Underwater systems,

12. The mining industry, …

13. Spiral Cables