General Details

Technical Specifications

| Operating temperature | -30 °C … +70 °C |

| Bending radius min. | 10 x D |

| Impedance | 50 ± 2 Ω |

| Capacity | 78,5 ± 2 pF/m |

| Propagation speed | %85 ± 2 |

| Insulation resistance min. | 2 G Ω x km |

| Operating voltage max. | 2000 V |

| Test voltage | 5000 V |

| Standards | EN 50117, IEC 61196 |

| fire performance | Vertical flame spread EN 60332-1-2 (PVC-HFFR) Corrosive gas EN 50267-2-1/2 (HFFR) Smoke density EN 61034-2 (HFFR |

| Attenuation @20 °C max | 30 MHz 2,38 dB/100m 50 MHz 3,01 dB/100m 150 MHz 5,10 dB/100m 220 MHz 6,18 dB/100m 450 MHz 8,96 dB/100m 900 MHz 13,02 dB/100m 1500 MHz 17,33 dB/100m 1800 MHz 19,24 dB/100m 2000 MHz 20,45 dB/100m2500 MHz 23,30 dB/100m 5800 MHz 38,92 dB/100m |

| return loss | 30-1000 MHz > 23 dB 1000-3000MHz > 20 dB |

| Screen attenuation | 30-3000MHz ≥ 90 dB |

Usage areas

RWC Low Loss cables are cables produced with a new generation 3-layer physical foam technology. It provides high performance for 50 ohm broadband wireless applications. RG type provides lower loss, higher propagation speed and better RF shielding than conventional cables. It is usually terminated with BNC, TNC, SMA and N-Type connectors.

It is used in radio and wireless communication systems, RFID, WiFi, Distributed antenna systems (DAS), Wireless internet (WISP), Global positioning (GPS) systems, defense industry and telecommunication systems. While the sheath material is polyethylene, it is preferred in open air and underground applications, while it is preferred in places where it should not be affected by fire conditions and be halogen-free.

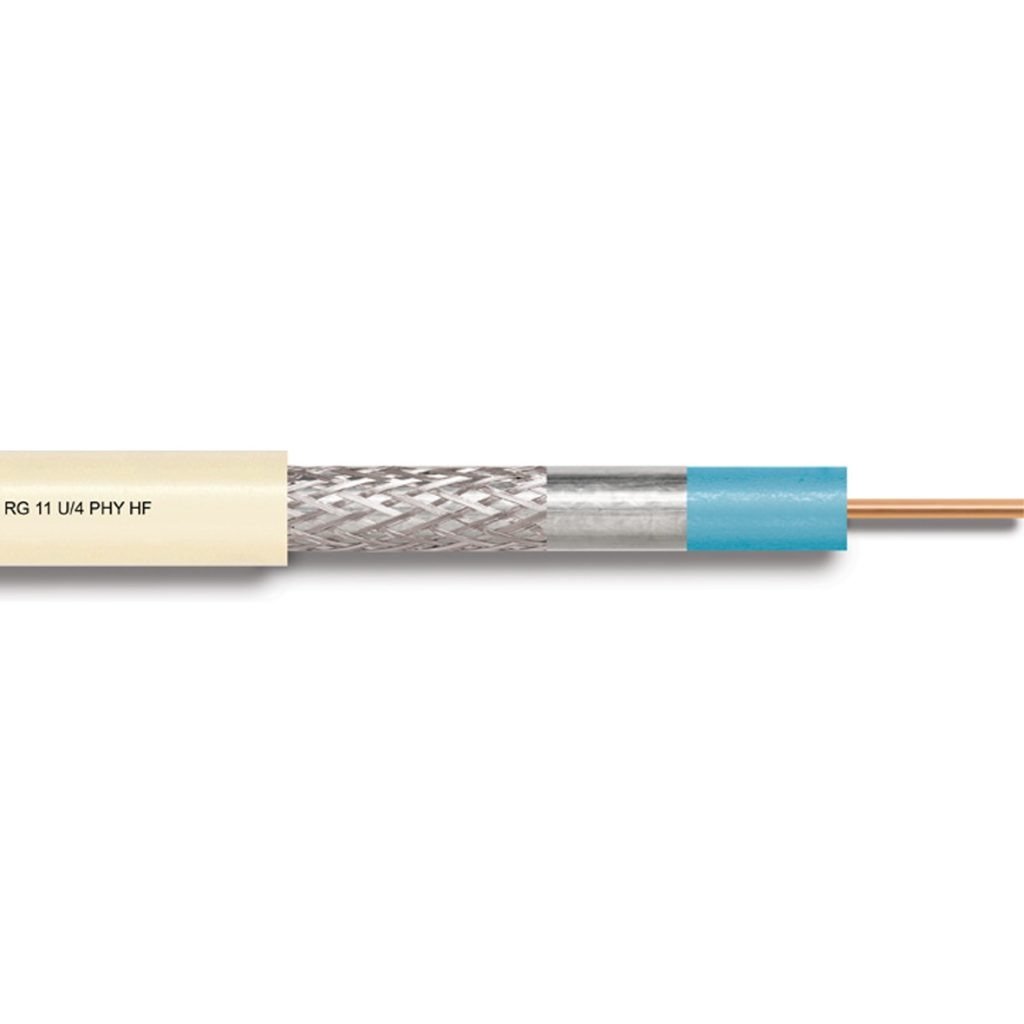

Cable Structure

| Conductive | Electrolytic copper wire, Ø 2.70mm Class 1, IEC 60228 |

| Insulation | Physically foamed PE, Ø 7.20mm 70°C, EN 50290-2-23 |

| Screen | Al-Pet-Al foil min.100% coverage tinned copper wire braid 85% coverage |

| Sheath | PVC – RAL 9011 Black, Ø 10,2mm TM51 70°C, EN 50290-2-22 LLDPE – RAL 9011 Black, Ø 10,2mm 80°C, EN 50290-2-24 HFFR – RAL 9011 Black, Ø 10,2mm 70°C, EN 50290-2-27 |