Where are NYAF and TTR Cables Used?

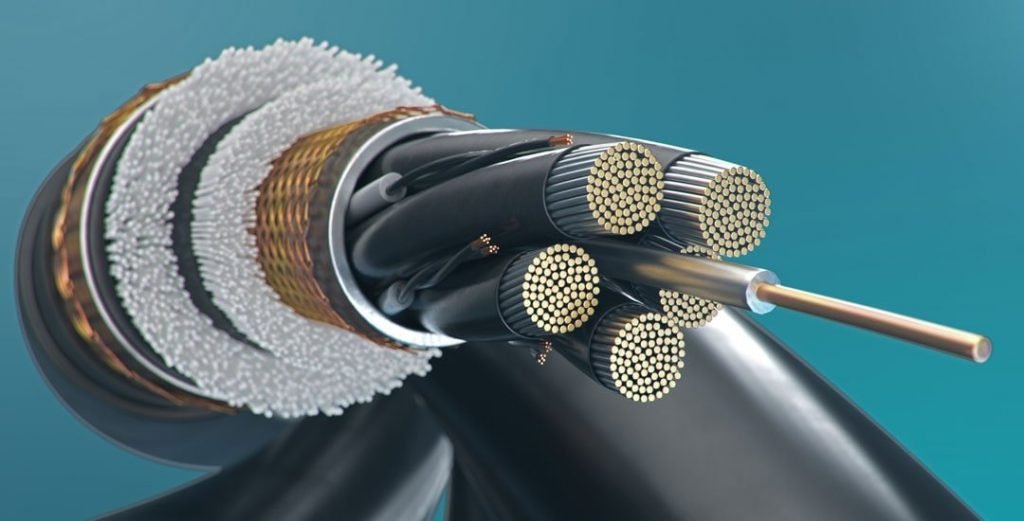

Today, the use of cables is needed in many different areas and there are many different types of cables. NYAF cables are one of the most preferred cables in recent years with their different types and the advantages they provide. The type of cable that is produced from thin, multi-stranded and B group wires in sections from copper to 0.5-500 square millimeters and thermoplastic is used as insulator is called NYAF cable. It is possible to produce NYAF cables, which can be multi-strand or thin single-body, in sections between 0.5 – 500 square millimeters. NYAF cables, which are less frequently used in indoor installation applications than NYA cables, can resist heat up to an average of 105 degrees.

Despite their thin structure, NYAF cables have many different wires in their structure. NYAF cables are very efficient when used in the right areas and for the right purpose. However, in order to obtain high-level performance from NYAF cables, it is possible to have a detailed knowledge of all the features of NYAF cables during the selection phase and thus to prevent problems arising from incorrect cable selection.

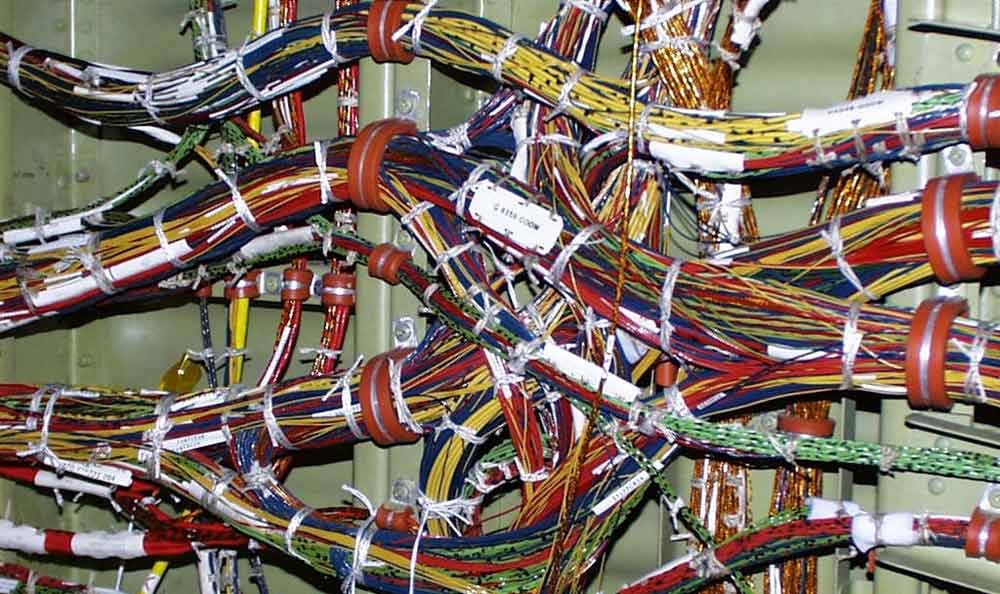

NYAF cables, also called grounding cables, have a wide range of uses. NYAF cables can be used especially in the terminal connections of automatic controls, in the connections of portable and mobile devices, in electrical panels, in different cable ducts in humid areas. The usage areas of NYAF cables are generally concentrated in dry places, under and over plasters, in control circuits in panels. NYAF cables, which are suitable for use in jobs requiring flexibility, have the feature of being one of the most frequently used cables in the assembly of electrical and electronic products.

NYAF cables are produced in such a way that they can be used in mobile devices as well as in fixed areas and inside panels. If the NYAF cable is to be used outside of the plaster, a longer service life can be achieved by using an additional protection. Since their thin and flexible structure becomes a great advantage, NYAF cables are often preferred in applications requiring flexibility. At the same time, NYAF cable types can be used in car parks, basements or areas with similar characteristics, fixed with crochets or inside cable ducts. It is also possible to use NYAF cables as mobile cables in outdoor uses.

Cable Selection Should Be Made According to Application Area and Purpose

TTR cable is the cable in which the conductors formed by bringing together many thin copper wires and covering them with PVC are brought together with a PVC sheath and filled with PVC filling between them. TTR cables can also be expressed as NYAF cables collection. There may be different numbers of conductors covered with PVC in the structure of TTR cables. Each core of PVC cables also contains many conductive wires within itself. If one of the TTR cable types with features suitable for the usage area and purpose is selected, it is possible to obtain the highest level of performance from the use of TTR cables.

TTR cables, which are made of fine copper wire due to their external structure, have PVC coating feature. Classification of TTR cables can be made according to the number of cables in them and the amount of cross-section on the cables. TTR cables with a cross section of 1.5 mm and 2 cores are called 2×1 5TTR cables. Since the number of cores in the cables is accepted as an indicator of the durability of the cables, it is one of the most important issues to consider when choosing the cable, safety and TTR cable current carrying capacities. The high number of cores in the cables has the feature of being an extremely important advantage in terms of both safety and efficiency. However, the current carrying capacities of TTR cables can vary in the range of 3 – 32 A, depending on the materials used in the production of the cable and the number of cores.

TTR cables, which have a flexible usage area, can be widely used in the electricity sector due to their structural features. TTR cables must have appropriate cross-sections for their area of use. Generally, TTR cables can be used as mobile cables in wet and humid areas that do not have the features to force the electrical installation, in lighting installations that are not found in the main electrical installation, but in places where there is a need to add to the installation, in the internal mechanisms of electronic devices and with a higher performance than the cables from which energy is supplied.

TTR cables are considered safe because they have PVC insulation. Although TTR cables are generally preferred for materials used in homes, they can also be used in electrical installations where mechanical stress is minimal. TTR cables can be used in construction sites, in cases where additional installations are required and in extension cables, as well as in humid and wet areas where mechanical stress is less. However, the cross-sectional areas of the TTR cable to be used should be carefully selected, and the length of the cable and the size of the load to be fed should be taken into account during the selection process. In order to determine these values in the most accurate way, the voltage drop calculation should be made and the current carrying capacity of the cables should be checked. TTR cables can also be used in household appliances with electrical connections where there is slight mechanical stress.